ABOUT US

ABOUT

OUR COMPANY

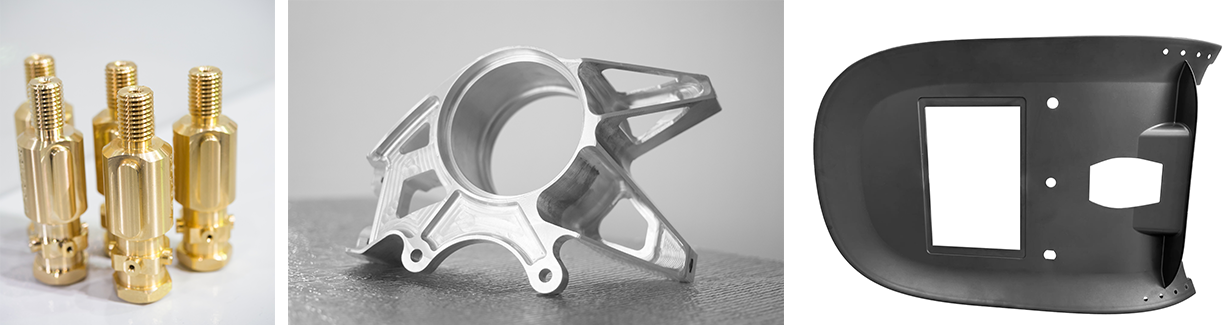

XYT Company mainly produces multi-axis CNC machining and lathing parts, including those of customized special sizes, precision, or other requirements. We also serve as a manufacturer of large-size injection parts and rubber parts for overseas customers. We are honored to say that we have earned a good reputation for presenting delicate products to satisfy our customers.

About us

XYT Company mainly produces multi-axis CNC machining and lathing parts, including those of customized special sizes, precision, or other requirements. We also serve as a manufacturer of large-size injection parts and rubber parts for overseas customers. We are honored to say that we have earned a good reputation for presenting delicate products to satisfy our customers.

Updates